Did you know EVERY Onefinity CNC can cut material bigger than the cutting area of the machine? That's right!

It's called tiling, and, because of the open-ended design of all Onefinity CNC machines in the Y axis, you can cut longer material than your cutting area! Infinitely longer! (get it? Infinite possibilities? :P )

Most major CAD software (like @vectric and @carveco design software we sell) includes this feature for free!

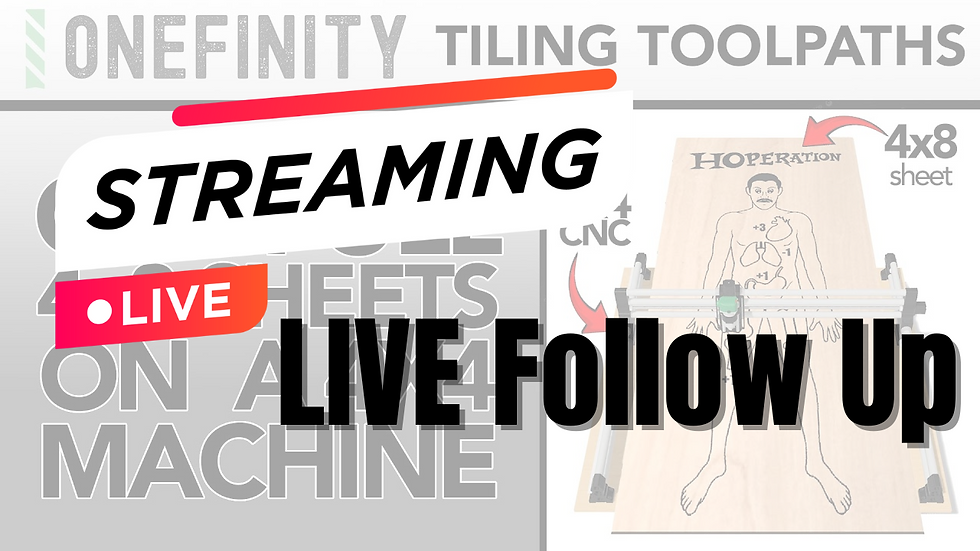

In this episode, Morgan shows us how he cut a full 4’x8’ sheet of plywood on a Onefinity Foreman (4'x4' cutting area), by tiling the toolpaths in VCarve. This process allows you to cut designs larger than , and on material larger than your CNC's fixed cutting area.

By feeding the material through the Y axis, tiling breaks the toolpaths up into sections that fit within the machine's cutting area, and executes the operation one tile at a time. And for this project, the best and only logical way to demonstrate tiling was to cut a life-sized Operation cornhole board.

Big thanks to @FierySquirrelArt for "Operationifying" Morgan and @TotalBoat for providing the epoxy!

Morgan will be going live on YouTube Monday 22nd, 24 to take your questions on this project! Join us and get your questions answered! Turn on those notifications on our YouTube channel and follow us on social media to get notified when we go live so you can join in!

.png)

Can someone from Onefinity Please Please address the reason that you can not or will not build a 4x8 machine? Is it the cost, engineering, or manpower? It seems to be something that could be put to bed once and for all, as there are many people moving past 4x4 now. It would be a service to your community of owners and potential owners to note what your future plans might be. Thank you!!